Pneumatic

In pneumatic applications that combine high linear speed, miniaturization, effective sealing, and intensive use, Techné provides seals with good slip coefficient, high resistance to abrasion, and innovative profiles.

A ISO TS 16949 certified facility, advanced quality control tools, and an experienced technical team give Techné all the resources to support its customers' developments.

Contact us

Main applications and products

Techné seals are used in various pneumatic applications, including:

- Differential distributor housing seals with retaining lugs

- ZOP seals for high-speed and minimal footprint applications

- Precision lip seals with guaranteed smooth edges

Techné offers comprehensive sealing solutions for pneumatic cylinders:

- O-rings

- X-rings

- Scraper seals

- Composite piston seals

- Composite rod seals

- Custom molded parts

The materials used include elastomers (such as NBR, HNBR, FKM), polyurethane (PU), and PTFE.

Order online

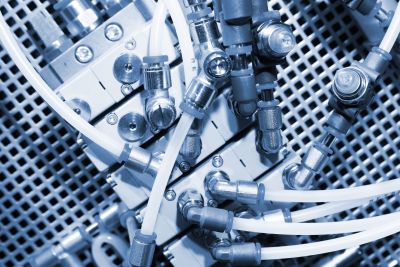

Inspection through automated sorting machine

Upon customer request, Techné conducts 100% inspection and sorting for both rotational and shaped parts, ensuring top-tier quality commitments with ppm-level quality assurance.

This inspection is applicable for parts with the following dimensions:

- Minimum outer diameter of 5 mm

- Maximum outer diameter of 55 mm

- Minimum height of 1 mm

- Maximum height of 8 mm

Specific packaging

To prevent deformation, Techné offers specialized packaging options, including:

- Air-filled pouches

- Use of intercalating materials tailored for the seals

- Thermoformed PVC or PET plates shaped to fit the seals

- Other custom packaging options available on request

For applications demanding high cleanliness standards, Techné packages parts within a cleanroom environment, utilizing a double-bagging process.

Contact usCoatings

At its coating department in Morancé, Techné provides seal coatings to enhance the seals' characteristics:

- T-Lub® facilitates seal installation in static applications.

- Permanent or semi-permanent T-Coat® improves natural slip properties and extends seal lifespan in dynamic applications, maintaining the seal's original qualities.

- T-Surf® ensures cleanliness and non-contamination of seals while preserving the original material properties.

- T-Color® addresses customisation needs and also enhances friction properties.