TCT bushings

Composition

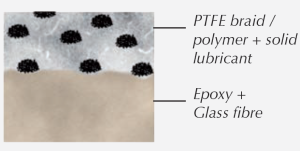

TCT bushings are made from two layers:

- A fibreglass epoxy resin structure which stiffens the bushing and provides rigidity

- A self-lubricating sliding layer: a layer of PTFE and highly resistant synthetic fibres, impregnated with PTFE-based solid lubricant

Recommendations

Techné recommends the following technical parameters for the use of TCT bushings:

Variant TC-FC

TC-FC bushings are wrapped with fibres and are impregnated with thermosetting resins. This light bushing has a PTFE layer which provides the bushing self-lubricating properties.

The bushing is characterised by its high load capacity and is particularly suitable for frequent starts and stops.

The TC-FC bushings have a dimensional range of 2.5 mm thickness. They can therefore be mounted instead of a wrapped bushing.

Advantages of TCT bushings

- TCT bushings are self-lubricating, no need for oil grooves.

- They are often used to replace bronze bushings for which maintenance and relubrication is required.

- TCT bushings have an excellent load resistance such as metal bushings with the same lifetime.

- Moreover, they can be set up in corrosive environment without damage thanks to their superior chemical resistance compared to other bushings.

Limitations of TCT bushings

TCT bushings have a specific dimensional range, especially in terms of thickness.

TCT bushings have a low resistance to steam

Applications

TCT bushings often replace bronze bushings in lifting equipment, construction machinery, transport and agricultural equipment. They are also preferred in marine equipment.