TU and TU-B bushings

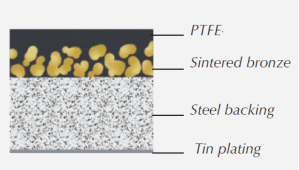

TU bushings are self-lubricant and composed with four layers. They are recommended for all types of movements (rotation, translation and oscillation).

Composition of the TU bushings:

- A steel backing for an optimal mechanical resistance. On the outside, it is protected with a tin or copper plating against corrosion

- A sliding layer made of porous sintered bronze with three functions: thermal conductivity, dimensional stability and absorption of the solid lubricant

- A layer of PTFE-based solid lubricant with excellent wear and frictional resistance properties

Recommendations

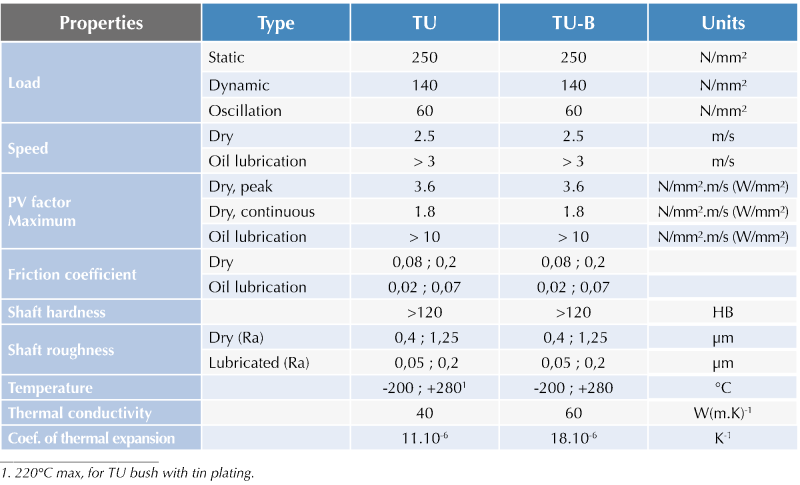

Techné recommends the following mechanical characteristics for the use of TU bushings:

Variants

- TU-B bushings

The composition of the structural layer is different between the TU-B bushing and the TU bushing. For the TU-B bushing, it is replaced by a layer made of bronze.

A structural plate made of bronze has a lower mechanical rigidity than a plate made of steel. Since bronze has a high corrosion resistance and very good thermal conductivity, protection by tin plating is not necessary.

- TP4 bushings

The evolution of the TP4 bushing lies in the composition of the PTFE solid lubricant layer. It is mixed with fillers and polymers that enhance the mechanical resistance of the sliding layer. This improves the resistance of the bushings towards oscillation or translation movements.

There are also derived products of the TU bushing and its variants such as support discs or flange bushings.

Contact us

Advantages

- TU bushings offer very good wear resistance and a good PV factor depending on the operating conditions.

- They work both dry and with lubrication.

- TU bushings have a wide temperature range resistance (-200 °C/+280 °C).

Limitations

- TU bushings need a clean operational environment. Different kinds of contamination can damage the PTFE layer and lead to premature abrasion.

- TU bushings should not be used in contact with seawater. For applications with seawater TU-B bushings can be used as an alternative.

Applications

TU bushings are multipurpose. They can be used for industrial applications, in professional equipment and in consumers’ households too: printing, robotics, conveyance, automotive, appliances, weight benches, etc.