X-rings

The X-ring or JT4 Techné, is a four-lobe seal (double-acting). It features an X-shaped profile, hence the name X-ring. When subjected to pressure, the symmetrical shape of the quadrilobe seal enhances the sealing quality and prevents the seal from rolling in its housing. Its dimensions are defined in the same manner as those of an O-ring.

Order online

Key applications of the X-ring

The X-ring was designed as an alternative sealing solution to the O-ring. It can be installed in place of an O-ring. The X-ring provides better sealing and lower friction than the O-ring in dynamic applications. Due to its shape, the X-ring creates dual sealing, distributing the load and stabilizing the seal. A grease reserve can be stored between its lobes to improve sliding.

The primary applications of the X-seal include:

- Various industrial applications

- Medical and pharmaceutical equipment

- Agricultural machinery

- Food equipment

- Industrial valves

- Automotive engines

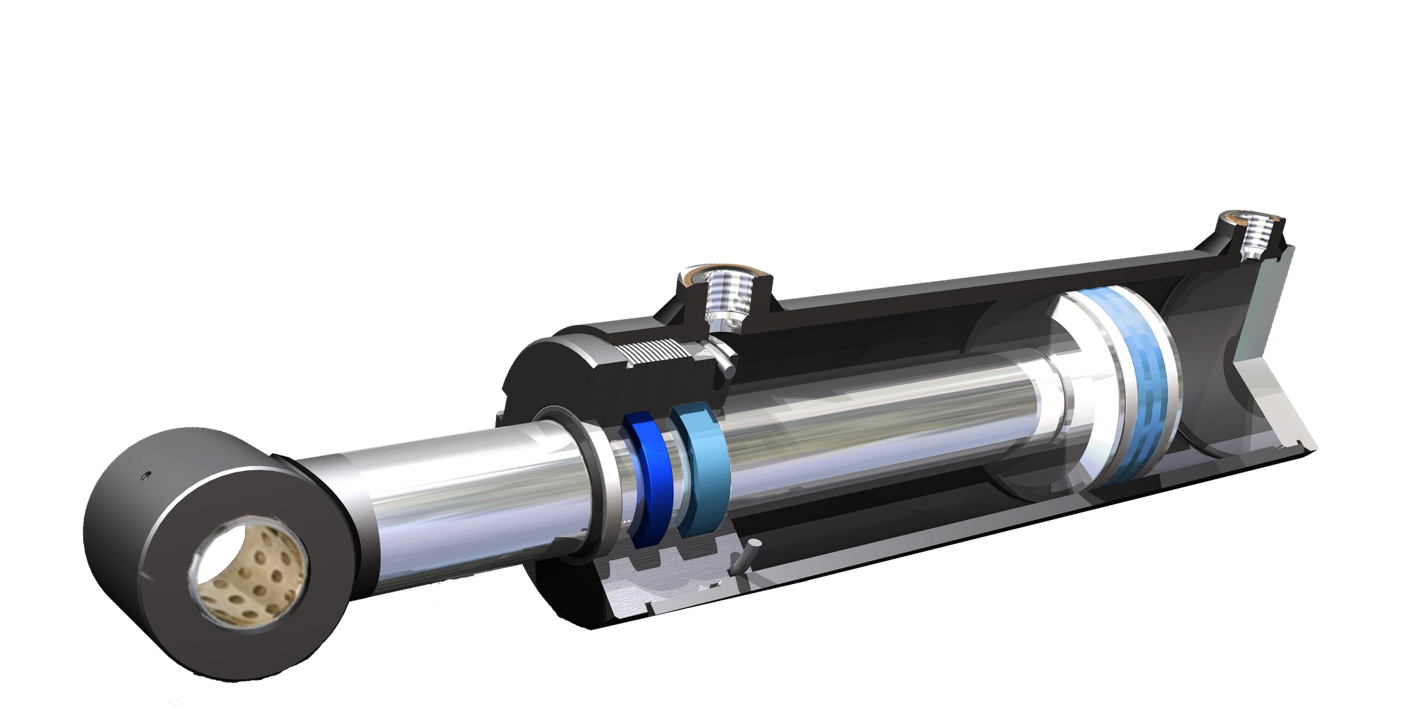

- Hydraulic fittings

Application limits

Pressure

Static:

- 50 bar without back-up ring

- 400 bar with back-up ring

Translation :

- 50 bar without back-up ring

- 300 bar with back-up ring

Rotation :

- 150 bar with back-up ring

Speed

Translation :

- 0.5 m.s⁻¹

Rotation :

- 2 m.s⁻¹

For more demanding translation applications, hydraulic or pneumatic seals can be used.

For more demanding rotational applications, Techné recommends using sealing rings.

Different X-ring materials

Depending on temperature, pressure, usage speed, and the chemical environment in which the X-ring will be used, Techné offers various materials. The Techné engineering team assists the group's customers in material selection.

Techné keeps the range of X-rings in stock in the following materials:

- NBR (nitrile)

- NBR + MoS2

- FKM

Other materials are available upon request:

- HNBR

- EPDM

- VMQ (silicone)

- FFKM

- CR

Approvals

Upon request, Techné provides X-rings with the following certifications:

- Food contact: FDA, CE 1935/2004

- Drinking water: WRAS, ACS, CLP, UBA

- BAM

- Gas : EN 549

Quality

Molded Techné X-rings adhere to strict quality standards:

- AS568 standard for tolerances (ID and CS)

- 3601-3 Grade N standard: corresponds to seal quality on the cross-section (visual defects)

Techné easily manufactures small series of JT4 Techné seals through machining. This manufacturing process is particularly suitable for very small quantities.

In collaboration with its subsidiary Créat, Techné offers custom-molded X-Rings in small quantities within 2 weeks.

Coatings

At its Morancé workshop, Techné carries out coatings on its X-rings.

Each coating serves a specific purpose:

- T-Lub® facilitates the installation of X-ring s, especially in static applications.

- T-Coat® is a permanent or semi-permanent treatment. It enhances natural sliding properties and the lifespan of X-rings, particularly in dynamic applications, while preserving the initial properties of the seal.

T-Surf® ensures cleanliness and non-contamination of X-ring seals while retaining the original material properties.

T-Color® fulfills marketing or identification needs by tinting the surface of X-rings. It also improves friction properties. Techné offers RAL and PANTONE color palettes.