Spring energised seals

The Techné energized seal is used either for high or low rotation and translation speeds, wide positive or negative temperature ranges, or whether the seal is in contact with corrosive fluids. SPRING Energized seals can replace most conventional seals.

Thanks to its very wide temperature range (-250 °C to +300 °C), Techné spring energized seals are a good alternative to elastomer materials, which are often limited when faced with high temperatures and aggressive environments.

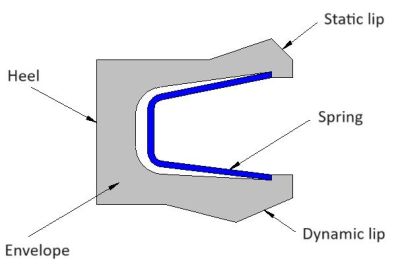

The spring energized seal consists of a PTFE active part and a spring (expander). The spring ensures a good seal at both low and high pressures. It also compensates wear on the PTFE casing under high loads.

Order online

There are 2 basic profiles of spring energized seal:

Energized seal with V-spring

Energized seal with coil spring

These profiles are available in several variants depending on the application:

- The elastomer ensures that no contaminants can be trapped in the cavity.

- This profile is intended for a food application.

- This type is used in high-pressure situations to keep the seal in place.

Improved resistance to extrusion, temperature, and pressure.

- Recommended profile for rotary or oscillating shaft applications.

- The flange is tightened into the housing to prevent any rotation of the seal with the shaft.

Assembly

There are 2 types of mounting

- Radial (e.g. rod and piston), for predominantly dynamic applications

- Axial (e.g. flange seal), for predominantly static applications

- Internal axial: if pressure comes from the inside

- External axial: if pressure comes from the outside

It is recommended to install spring energized seals in an open housing, and to lightly oil the components before assembly. The housing must be clean and free of sharp edges.

Applications

The spring energized seal is designed for use in a wide range of applications. It offers improved sealing performance.

Its benefits include

- Universal chemical resistance

- Wide temperature range

- Minimal friction (even when dry)

- Use at high pressures

- Use for reciprocating, rotating or static movements

- High abrasion resistance

- Low space requirement

- Resistance to high speeds

Pressure

- Dynamic application: The spring energized seal can withstand pressure up to 50 MPa.

- Static application: The spring energized seal can withstand pressures of up to 120 MPa.

Speed

- Translational movement: Maximum speed is 10 m/s.

- Rotational movement: maximum speed is 2.5 m/s.

Materials

The main material of the spring energized seal is virgin PTFE or filled PTFE:

- Filled between 5 and 40%

- Improved wear resistance

- Recommended for static applications, not recommended for dynamic applications (lower coefficient of friction)

- Filled between 10 and 35%

- Improved resistance to wear and creep

- Recommended for high-speed dynamic friction applications

- Filled between 5 and 15%

- Good thermal conductivity

- Low coefficient of friction

- Filled between 40 and 60 %

- Improved wear behaviour and very good creep reduction

- Good thermal conductivity

- If combined with MoS2 or graphite, improved coefficient of friction

- Lors d’une application statique, diminution du coefficient de frottement statique

- Amélioration de la conductibilité thermique