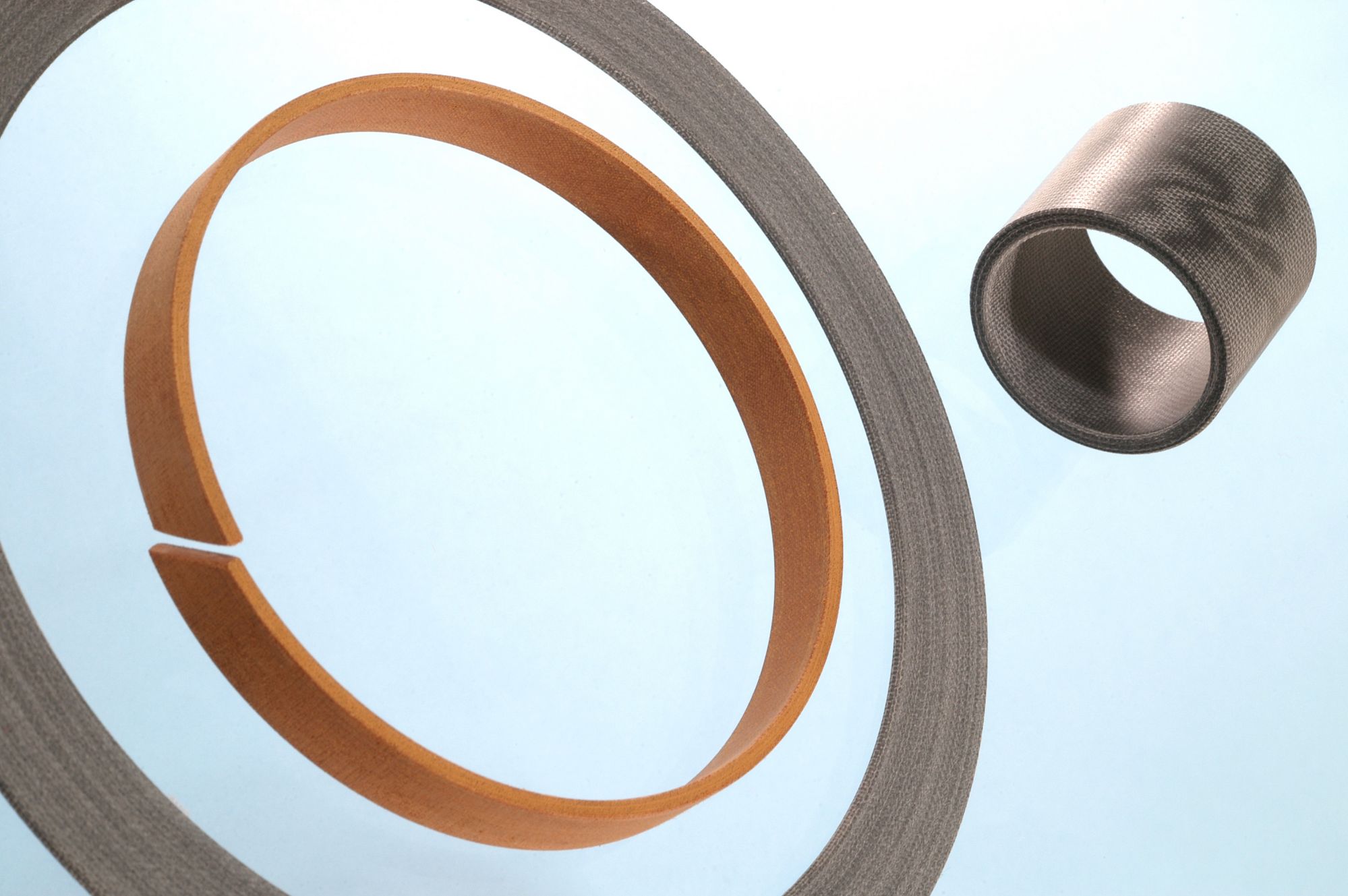

Guiding rings

Hydraulic guiding rings are components used in hydraulic or pneumatic systems to ensure the precision and stability of translational and rotational movements. They are, therefore, crucial for sealing systems. Primarily employed in cylinders, they can be found in applications such as machine tools, presses, robots, lifting equipment, and material handling.

Most Guiding rings today are non-metallic, offering excellent friction coefficients and wear resistance. They can also accommodate angular movements. Guiding rings contribute to operational cost optimization through improved energy efficiency and reduced machine downtime. Typically assembled in a closed groove, they are easy to install and replace.

Order online

Profiles

- Manufactured from glass fiber-reinforced POM.

- It operates at a maximum speed of 1 m/s and within a temperature range of -30 °C to 100 °C.

- The FR profile is used in high-speed hydraulic cylinders.

- Made from phenolic resin and cotton fiber.

- It operates at a maximum speed of 1.6 m/s and within a temperature range of -40 °C to 130 °C.

- The WEARTEC T1 profile is used in high-load applications.

- Constructed with bronze-filled PTFE.

- It operates at a maximum speed of 15 m/s and within a temperature range of -200 °C to 200 °C.

- The TECBZ profile offers excellent temperature resistance and extended chemical compatibility, with a low friction coefficient.

- Composed of synthetic fiber, polyester resin, and PTFE.

- It operates at a maximum speed of 1 m/s and within a temperature range of -40 °C to 120 °C.

- The TECKOT profile has extended chemical compatibility and is often used for maintenance and repairs.

Recommendations

- Rod surface finish: Ra < 0.4 μm

- Housing surface finish:

- Groove flanks: Ra < 3.0 μm

- Groove bottom: Ra < 1.6 μm

Techné offers Guiding rings made from roll Guiding strips.

These segments are commonly used for troubleshooting.