Piston seals

Hydraulic piston seals are crucial components in hydraulic systems. They prevent oil leakage between the piston and the cylinder of a hydraulic cylinder. Piston seals are subjected to high pressures and changing temperatures, so it is important to choose high-quality materials based on the system requirements to ensure proper system operation. Piston seals can be made from various materials, such as NBR, PTFE, or POM, each of which has its advantages and disadvantages.

Hydraulic piston seals encompass several types of products that ensure the sealing of cylinders on the piston. They consist of compact seals JP3 and JP5, as well as composite seals.

The role of piston seals is essential for the proper operation of hydraulic cylinders as they ensure fluid sealing within the cylinder. Piston seals are installed in harsh environments, so they must be designed with specific materials compatible with oils and resistant to wear.

Order online

Applications

Piston seals are primarily found in markets containing standard or specific hydraulic cylinders. They are commonly used in construction equipment such as tractors, excavators, or backhoes. They are also found in agricultural machinery such as combine harvesters or forage harvesters.

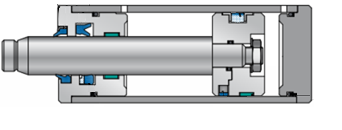

Presentation of the piston seals of a hydraulic cylinder

Products

- The JP3 seals are compact double-acting seals composed of 3 elements: an elastomeric ring and two guiding segments.

- They can withstand temperatures ranging from -30 °C to 200 °C and pressures up to 40 MPa.

- JP3 seals exhibit excellent resistance to extrusion and abrasion.

- The JP5 seals are compact seals composed of 5 elements: an elastomeric ring, two anti-extrusion rings, and two guiding segments.

- They can withstand temperatures ranging from -30 °C to 100 °C and pressures up to 40 MPa.

- JP5 seals exhibit excellent resistance to extrusion and can be installed in a closed groove, making them a more economical sealing solution.

- Techné's composite seals are made of materials with PU on the exterior and NBR on the interior.

- They withstand temperatures ranging from -30 °C to 100 °C and pressures up to 15 MPa.