TBL bushings

The TBL bushings are self-lubricating Bushes used for high-load applications.

Their composition is as follows:

- A high-strength structural base made of CuZn25Al6Mn4 bronze, which provides the bushing with good mechanical properties, as well as resistance to wear and friction.

- Inside the bronze structure, there are solid graphite-based lubricant inserts, enabling dry lubrication of the bushing even at high temperatures.

Applications

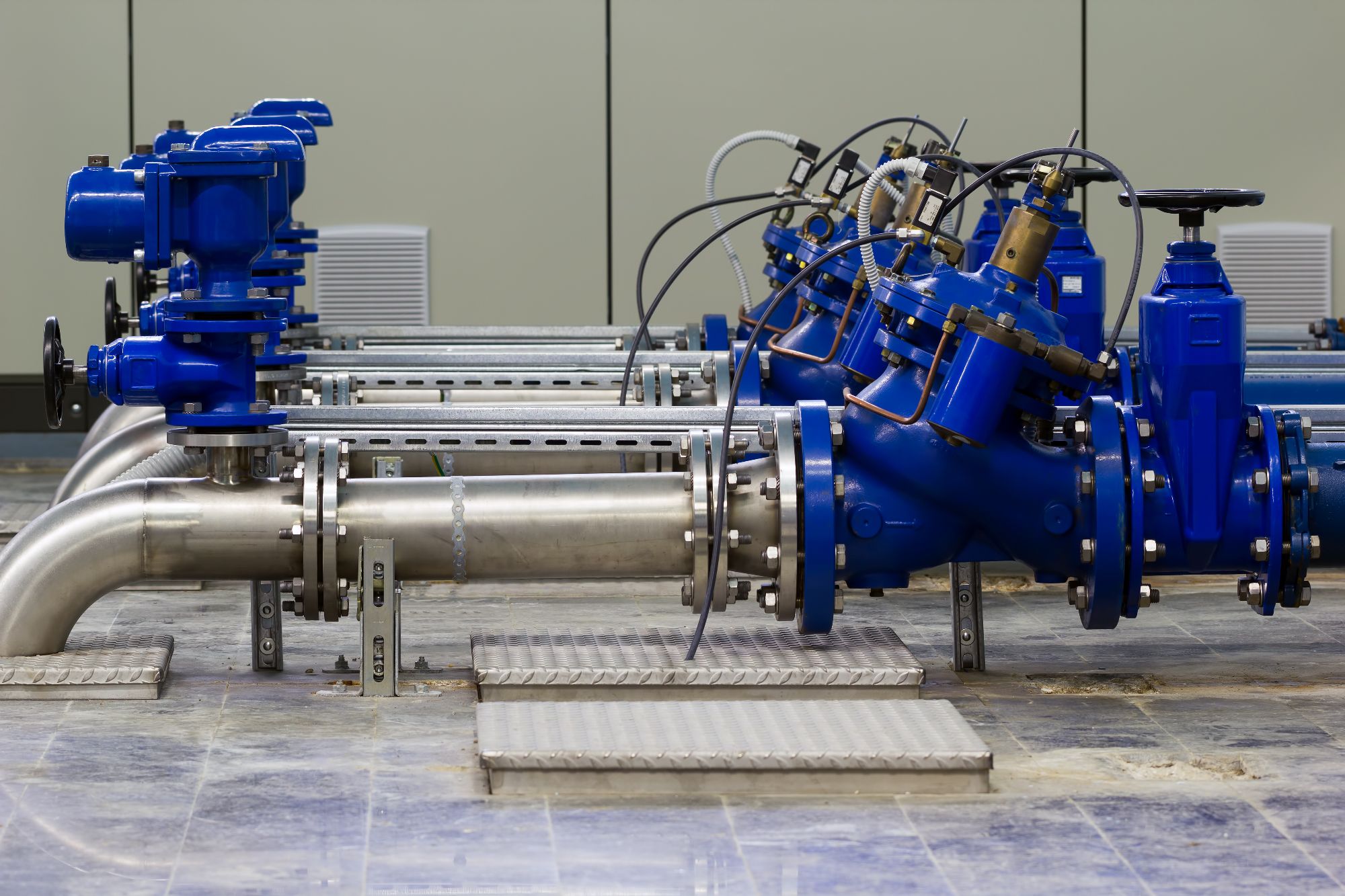

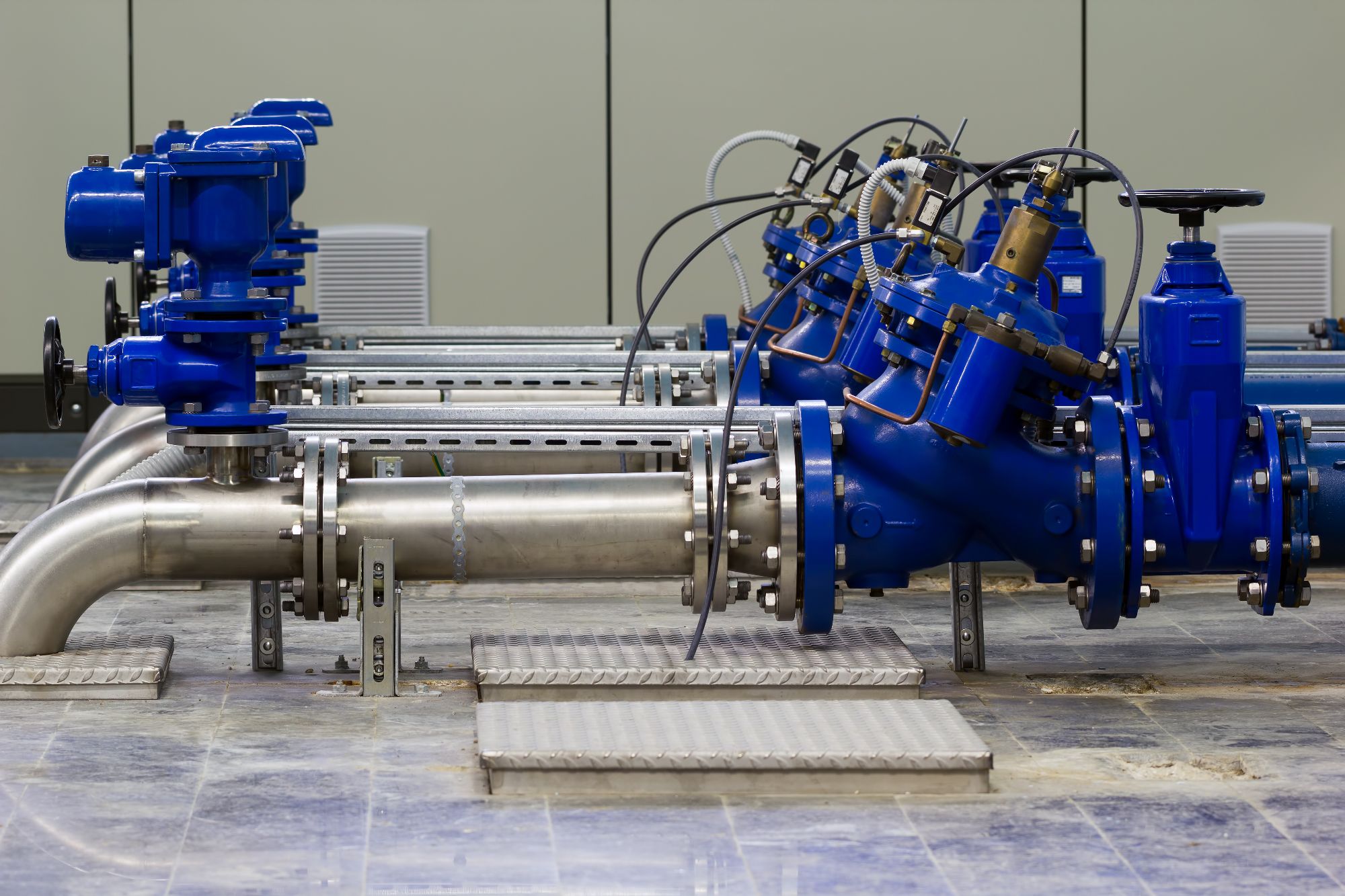

TBL bushes are primarily used in hydroelectric applications. They are also installed in certain sectors of heavy industry, such as steel mills, valves, injection molding machines, and applications in contact with chemicals, for example.

Recommendations

Techné recommends the following conditions for the use of TBL bushings:

Advantages

- Due to its high resistance the TBL bushing can be used under high loads.

- TBL bushings are self-lubricating, no maintenance is required.

- Use up to 300 °C

Limitations

- High weight

PLB bushings

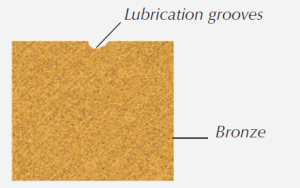

PLB bushings are machined bushes consisting of a single structural bronze plate that serves both as a sliding layer and support.

Recommendations

Techné offers several standard copper alloys to meet different customer needs:

CuSn12 compound has excellent friction properties under heavy loads (Rm>230 MPa). This alloy is mainly used in hydraulic systems and injection molding machines.

CuZn37Mn3Al2PbSi is a copper alloy developed for very high loads (Rm>345 MPa). It has an excellent friction coefficient and is mainly used for excavator arms or valves, for example.

CuAl10Ni5Fe4 is a copper-aluminum alloy with very good mechanical properties and high corrosion resistance (Rm>590 MPa). The alloy offers good abrasion resistance and ductility.

Techné can also manufacture PLB bushes based on the customer's material requirements.

To ensure proper functioning of the bushing, lubrication grooves are machined to improve lubricant circulation and enhance sliding properties of the bushing.

The fabrication of lubrication grooves follows the DIN ISO 12128:1998 standard and Techné's specifications.

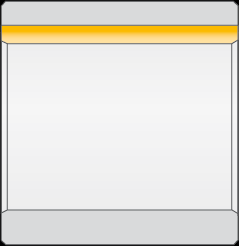

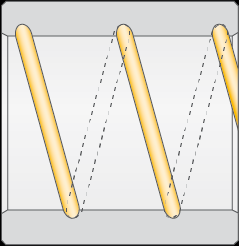

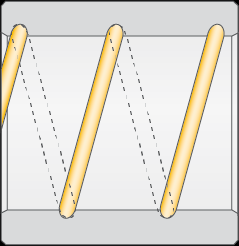

Type C

Longitudinal shape, non-outgoing

Applicable to TX, TY, TZ and TA

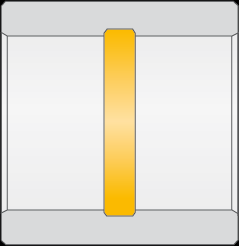

Type G

Longitudinal shape, outgoing (opposite to the fitting direction)

Applicable to TX, TY, TZ, and TA

Type H

Gorge longitudinale débouchante dans le sens d'insertion

Applicable to TX, TY, TZ, and TA

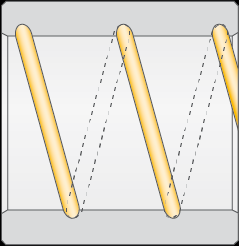

Type J

Longitudinal shape, outgoing

Applicable to TU, TX, TY, TZ, and TA

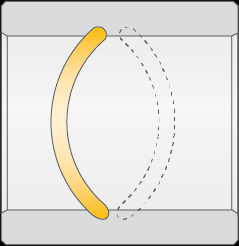

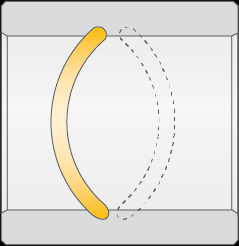

Type E

Circumferential shape

Applicable to TX, TY, TZ, and TA

Type N

Oval shape

Applicable to TY, TZ and TA

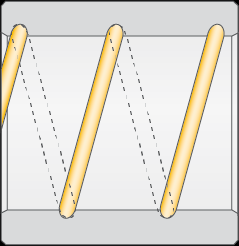

Type K

Screw shaped, right thread

Applicable to TY, TZ and TA

Type L

Screw shaped, left thread

Applicable to TY, TZ and TA

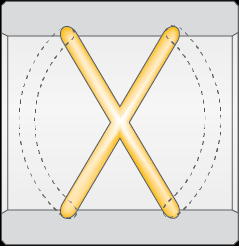

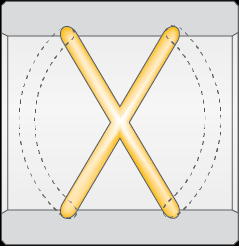

Type M

Eight-angled shaped

Applicable to TY, TZ and TA

Applications

The PLB bushings are primarily used for industrial pumps, conveyors, presses, heavy industries such as foundries or grinding of hard materials. They are also used in construction machinery as well as means of transportation.

Recommendations

Techné recommends the following conditions for the use of PLB bushings:

Unless specified by the customer, PLB bushes are produced according to the DIN ISO 4379 standard.

Advantages

- PLB bushes offer good load resistance and resistance to shocks.

- Their bronze structure provides good friction properties, corrosion resistance, and resistance to polluted environments.

Limitations

- Heavy weight.

- Lubrication and maintenance are necessary.

PLA bushings

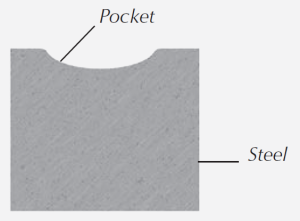

PLA bushings are machined bushes consisting of a single structural steel plate. They are designed for pivot connections with heavy loads and significant shock frequencies.

PLA bushings can also be formed from a steel strip. Techné advises using a wave-shaped slot in this case, as it facilitates assembly. It is an economical solution.

Recommendations

Techné offers several standard copper alloys to meet different customer needs:

C45 is an economical semi-hard steel that exhibits good mechanical properties (Rm > 700 MPa) and low hardening. It adapts well to thin bushing bushings.

42CrMo4 steel is a hard steel with excellent mechanical properties (Rm>700 MPa) and good hardening properties due to the addition of Cr and Mo elements. This alloy is suitable for thick bushings.

100Cr6 steel is a very hard steel with excellent mechanical properties (Rm>900MPa). Its hardness ranges between 55 and 60 HRc.

Techné can also manufacture PLB bushings according to the customer's material requirements.

For the proper functioning of the bushing, lubrication grooves are machined to enhance the circulation of the lubricant, thereby improving the sliding properties of the bushing.

The manufacturing of the grooves is done according to the DIN ISO 12128:1998 standard and Techné specifications.

Type C

Longitudinal shape, non-outgoing

Applicable to TX, TY, TZ and TA

Type G

Longitudinal shape, outgoing (opposite to the fitting direction)

Applicable to TX, TY, TZ and TA

Type H

Logitudinal shape, outgoing (fitting direction)

Applicable to TX, TY, TZ and TA

Type J

Longitudinal shape, outgoing

Applicable to TU, TX, TY, TZ and TA

Type E

Circumferential shape

Applicable to TX, TY, TZ and TA

Type N

Oval shape

Applicable to TY, TZ and TA

Type K

Screw shaped, right thread

Applicable to TY, TZ and TA

Type L

Screw shaped, left thread

Applicable to TY, TZ and TA

Type M

Eight-angled shaped

Applicable to TY, TZ and TA

Applications

PLA Bushes are primarily used in high-load applications in dusty environments, such as dump trucks, agricultural machinery, or construction equipment.

Recommendations

Techné recommends the following conditions for the use of PLA bushings:

Without any specific indication from the customer, PLB bushings are produced according to the DIN ISO 4379 standard.

Advantages

- PLA bushings offer good load resistance and high-frequency impact resistance.

- Their hardened steel structure improves their abrasion resistance.

- Good resistance to polluted environments.

Limitations

- Heavy weight

- Lubrication and regular maintenance are imperative.