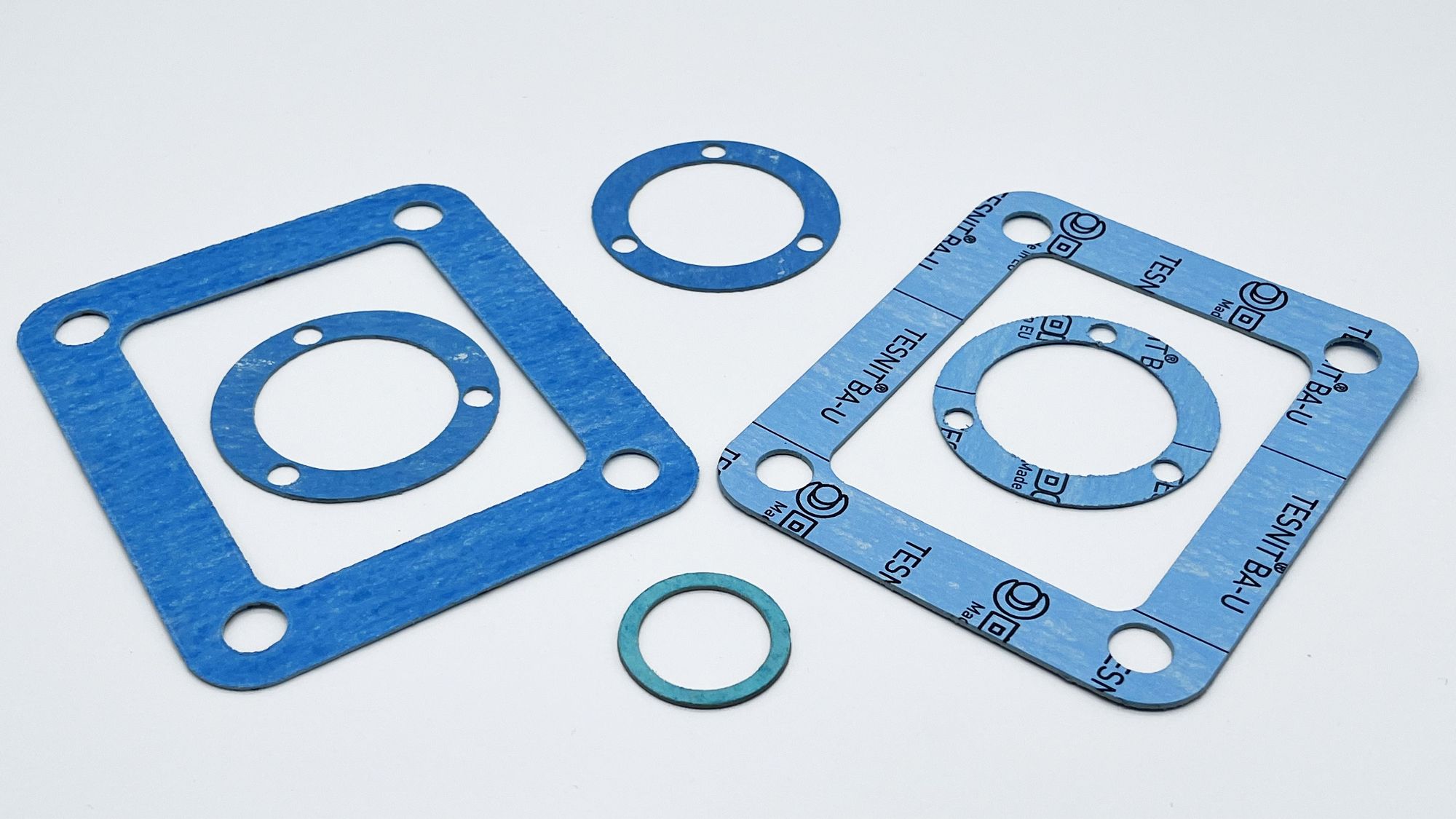

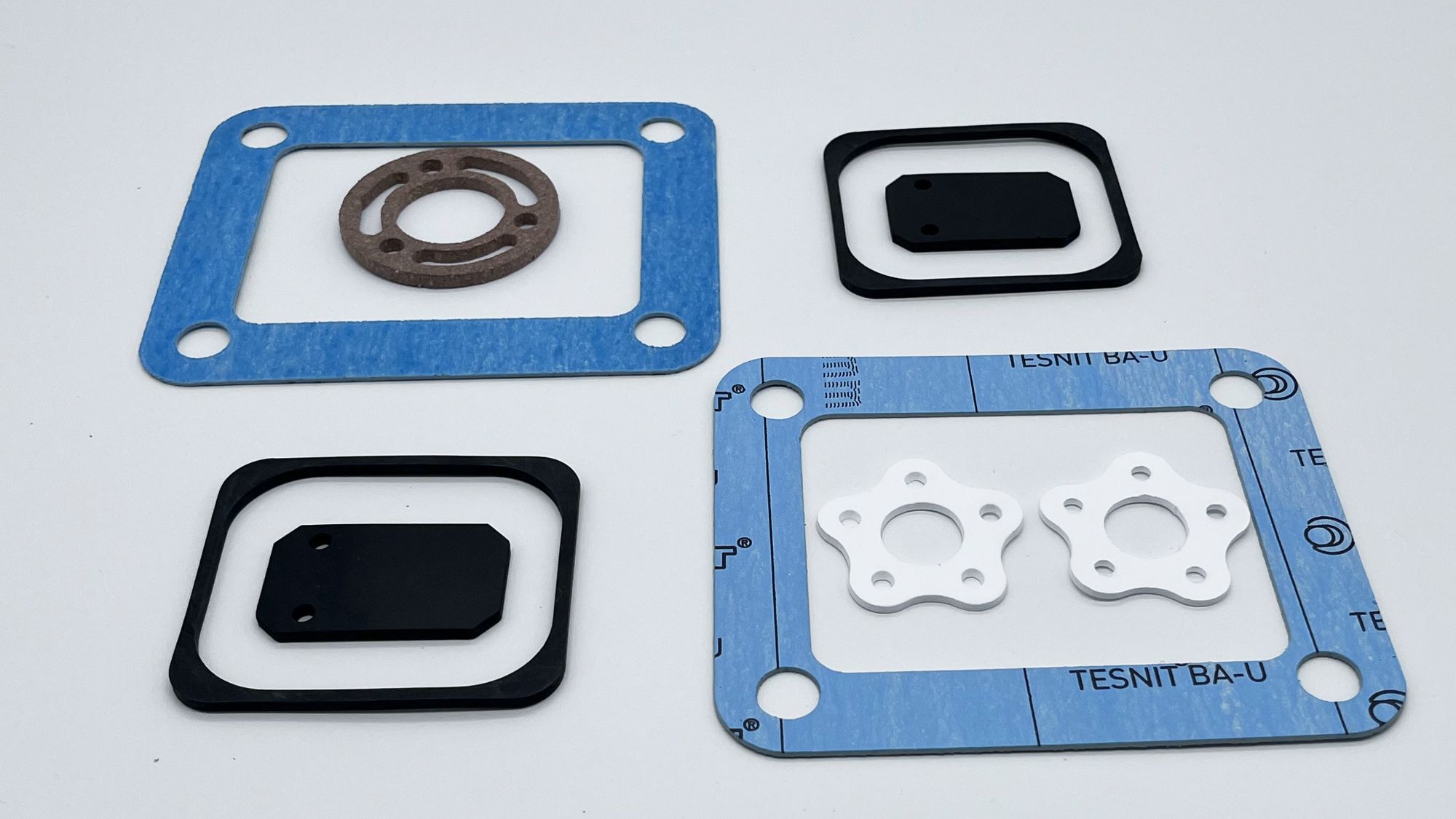

Cut gaskets

The Techné cut gasket is a flat gasket with 2 parallel faces designed to ensure tightness.

There are several cutting processes:

● Laser cutting

● Water jet cutting

● Press cutting

● Blade cutting

Chromex, a subsidiary of the Techné group, produces cut gaskets in small, medium, and large series. Thanks to this partnership, Techné guarantees strong responsiveness and short delivery times.

Discover Chromex - Techné's subsidiary

Applications

Cut gaskets can be used in various applications, including industrial and sanitary valves, petrochemicals, and the food industry.

Dimensional capabilities

- Maximum width: 1,500 mm

- Maximum length: 3,000 mm

- Maximum outer diameter: 1,500 mm

- Maximum thickness: 15 mm, others upon request

- Tolerances: +/- 0.2 mm on diameters

Materials and approvals

Cellular or compact elastomers:

- NBR (nitrile), NBR with 1 ply or 2 plies

- FKM

- EPDM, EPDM with 1 ply or 2 plies

- VMQ (silicone)

- FVMQ

- CR

- SBR

Plastics:

- Pure PTFE, PTFE GYLON®

- PU/TPU (thermoplastic polyurethane)

- PC

- Glass-filled PTFE

- PA (polyamide)

- PE

- PVC

Fibers:

- TESNIT®

- TESNIT® BA-U

- TESNIT® BA-GL3000

- TESNIT® BA-Soft

- Paper

- Red fiber

Upon request, Techné offers other materials such as graphite. For elastomer-based mixtures, Techné offers FDA, CE 1935/2004, 3A, USP VI, ACS, NSF 51, UBA, WRAS, EN 682, EN 45 545 certifications depending on the mixtures. This list is not exhaustive. Many mixtures are cut upon request to meet specific needs.