Static hydraulic seals

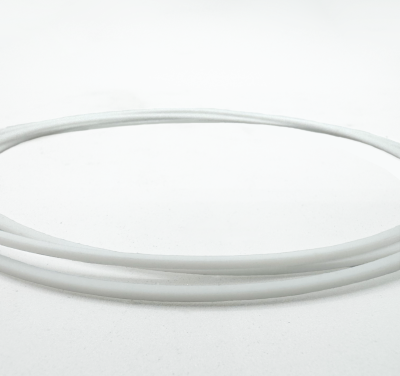

Back-up rings

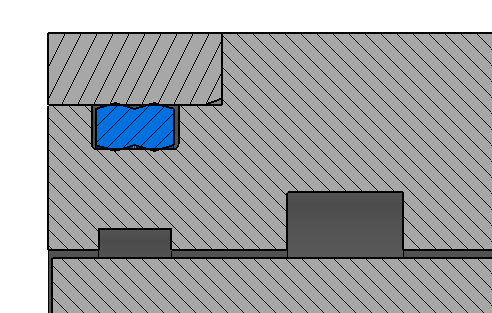

When a part of an O-ring comes out of its groove and gets lodged in the gap between the two sealing elements, it is referred to as extrusion. This phenomenon compromises the seal and leads to rapid deterioration of the O-ring.

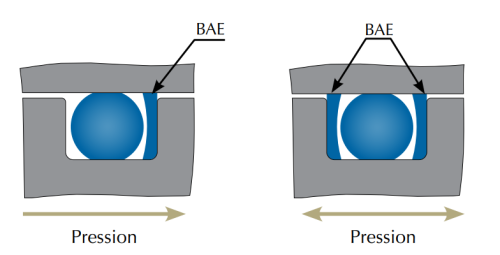

In combination with an O-ring or an X-ring, Back-up rings are used to overcome the problem of extrusion under high pressure. The back-up ring is placed on the opposite side of the pressure applied to the seal. In cases where pressure is applied from both sides of the seal (double-acting), two back-up rings are placed on either side. This is a simple, fast, and effective solution to implement.

Order online

Benefits and applications

Extended lifespan of the O-ring

Cost-effective solution with low sealing costs

Possibility to widen machining tolerance of grooves

Resistance to pressures higher than that of the O-ring alone (recommended from 50 bar for any system)

Back-up rings are used in systems with severe pressures or high risks of extrusion. Most often, they are associated with O-rings.

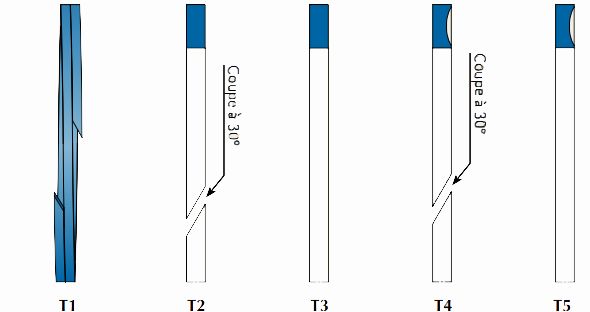

5 profiles of back-up rings

- Back-up ring T1: Spiral

- Back-up ring T2: ST8C (flat) with a 30° cut

- Back-up ring T3: ST8 (flat)

- Back-up ring T4: ST9C (concave) with a 30° cut

- Back-up ring T5: ST9 (concave)

Manufacturing process

Typically, elastomeric Back-up rings are obtained through moulding. However, upon request and for shorter lead times, Techné also offers machined parts. Plastic Back-up rings are obtained through machining.

Materials

The material choice is determined by the operating temperature, chemical resistance, and the hardness of the seal, which should be defined based on the application. The type of Back-up ring should be selected according to the applied pressure.

For various applications, chemical environments, and pressures applied to the Back-up ring, Techné offers several materials:

Elastomers (T2, T3, T4, and T5)

• NBR 90 IRHD

• FKM 90 IRHD

• HNBR 90 IRHD

Thermoplastic elastomers TPE (T2, T3, T4, and T5)

• PU 95 IRHD

Plastics (T1, T2, and T3)

• Virgin PTFE

• PTFE filled with carbon/graphite

• PTFE filled with bronze

• PTFE filled with graphite

• POM

• PA

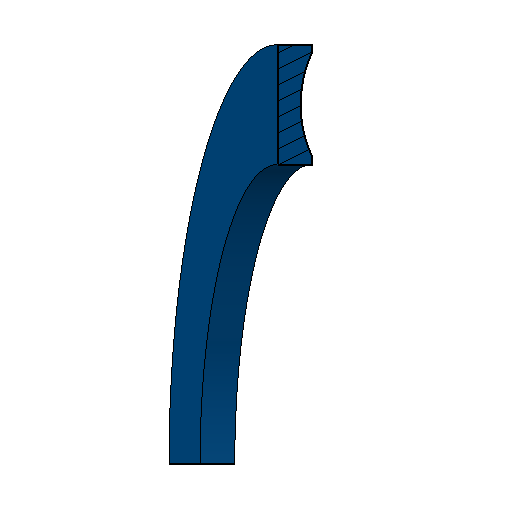

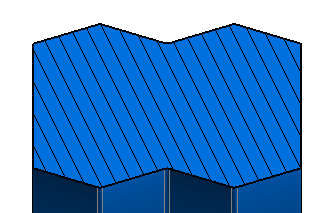

OP PU seals

The OP PU seal is a double-acting radial static seal made of polyurethane, designed for high-pressure applications.

It provides a high-performance alternative to the traditional O-ring + anti-extrusion ring combination, integrating both functions into a single component.

The combination of its profile and material ensures excellent extrusion resistance while providing reliable sealing. The seal also resists twisting (facilitating installation) and can withstand pulsating loads.

Benefits and applications

Good resistance to extrusion

Easy installation (no risk of twisting)

Double-acting function

Withstands high and pulsating loads

The OP PU seal is mainly used in hydraulic applications, standard cylinders and injection molding machines.