Inspection, packaging, and 100% sorting

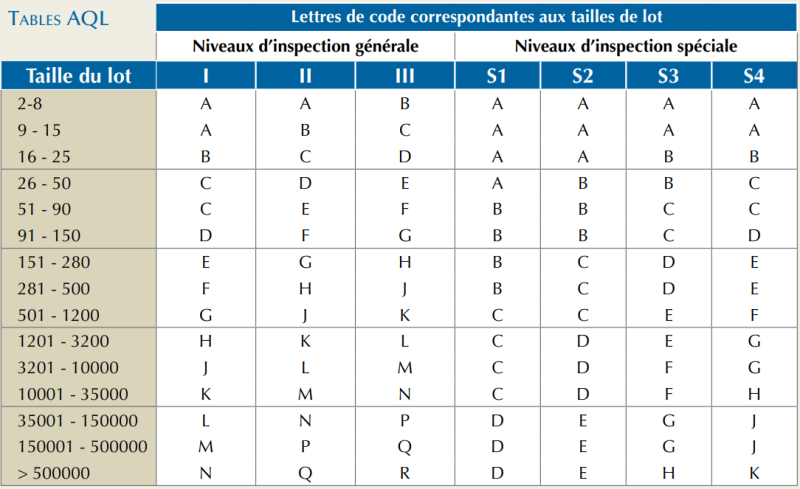

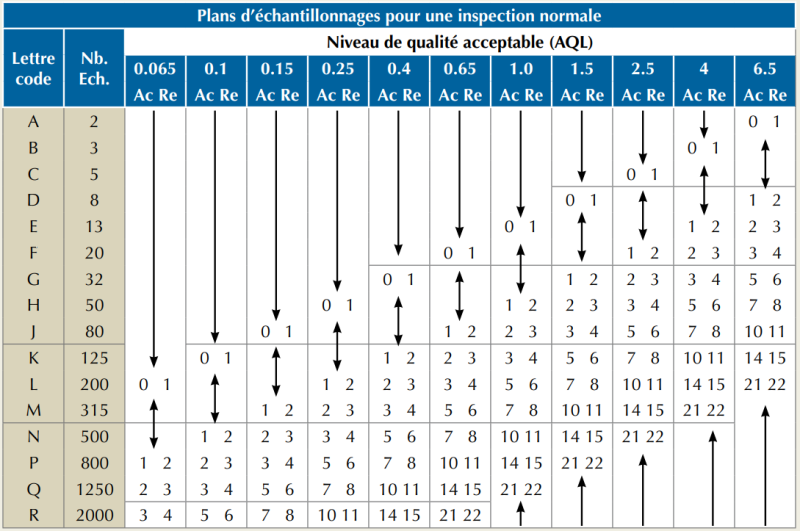

AQL Visual inspection

Techné standardly conducts a visual inspection using the Acceptable Quality Level (AQL) 1.0 level II standard as the decision criterion.

This method, widely used in the industry, is applied to a random sample of products once they are manufactured and packaged.

↕ Use the first sampling plan above the arrow

↕ Use the first sampling plan below the arrow

100% visual inspection

Upon request, Techné performs a 100% visual inspection of parts for surface defects such as material deficiencies, out-of-tolerance burrs, inclusions, and geometric defects like ovalization.

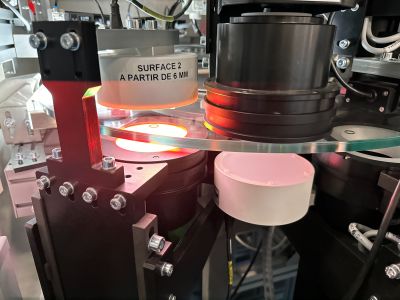

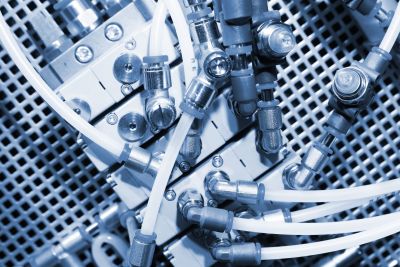

Inspection with automatic sorting machine

Upon customer request, Techné conducts a 100% inspection with sorting for both rotational and shaped parts, especially for automotive applications with quality commitments at ppm levels. This is feasible for parts with dimensions:

- Minimum outer diameter of 5 mm

- Maximum outer diameter of 55 mm

- Minimum height of 1 mm

- Maximum height of 8 mm

100% sorting

Elastomeric parts produced by Techné using injection or compression molding processes may have defects, especially in large production series. Additionally, material vulcanization can cause shrinkage depending on the mix.

These defects may involve incorrect dimensions due to material shrinkage during vulcanization, cut parts, or incomplete formations. Other statistically possible defects include deformed parts, ovalized parts, flatness defects, or parts stuck together. Techné offers 100% automatic sorting to eliminate parts with these production defects.

Application sectors and products

100% sorting is intended for clients operating in sectors with zero tolerance for defects and ppm commitments. Specific safety standards and regulations (Safety/Regulatory parts) might also require a 100% sorting solution. This solution is well-suited for critical assemblies and applications such as automated assembly lines.

The main sectors concerned are automotive, luxury, tire manufacturing, medical, and household appliances.

100% sorting can be applied to various elastomeric and plastic parts, as well as circular and custom-shaped components with dimensions ranging from outer diameters of 1.2 mm to a maximum of 50 mm and heights from 0.5 mm to a maximum of 9 mm.

Additional services of 100% sorting

For specific requests, the Techné design office is at the disposal of the group's clients.

Automated packaging

Customer labeling on the bag

Sorting by defect type or tolerance range

Statistical sorting result analysis

Verification of PWIS absence (LABS-free quality)

Coatings

Double bagging

Standard, cleanroom, or ultrasonic washing

Cleanliness measurement

Standard packaging

Techné products are standardly packaged in opaque UV-resistant and antistatic bags. This safeguards the parts from premature aging.

A quantitative check (measurement of total weight divided by the unit weight of the part) is performed during packaging. For easy handling, formats are standardized:

- GALIA standard cartons

- Carton weight < 25 kg

- Standardized pallets (e.g., dimensions 600 x 800, 800 x 1200, etc.) with easily manageable heights compatible with standard stock racks.

Cleanroom packaging

For applications demanding high part cleanliness, Techné offers cleanroom packaging for:

- Medical applications

- Very small diameter valves

- Automotive applications

- Pneumatic applications

Techné employs a double bagging process in such cases.

Specific Packaging

Upon customer request and to prevent deformation, Techné provides specific packaging solutions, such as:

Air-filled bags

Use of inserts tailored for gaskets

Grouping and wrapping parts in paper, then placing them in opaque bags

Thermoformed PVC or PET plates shaped to fit the gaskets

Washing

To meet higher cleanliness requirements, particularly in the electronics or food industry, Techné offers tailored washing solutions. These are collectively referred to as T-surf.®.